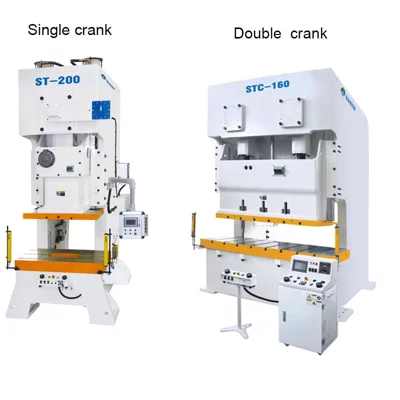

Composition and maintenance methods of punch feeder

This article provides an overview of a punch feeder, a special conveyor used for conveying granular, powdered, and sheet materials. The punch feeder operates by exerting pressure on the processed material through a die. The hydraulic cylinder gradually increases pressure as the contact time with the working material increases. Once the electromagnetic reversing valve receives a signal, the punching head resets. However, there may be instances where the pressure in the cylinder does not reach the set rated pressure due to time limitations. Nonetheless, the cutting process is completed.

Mar 05, 2024