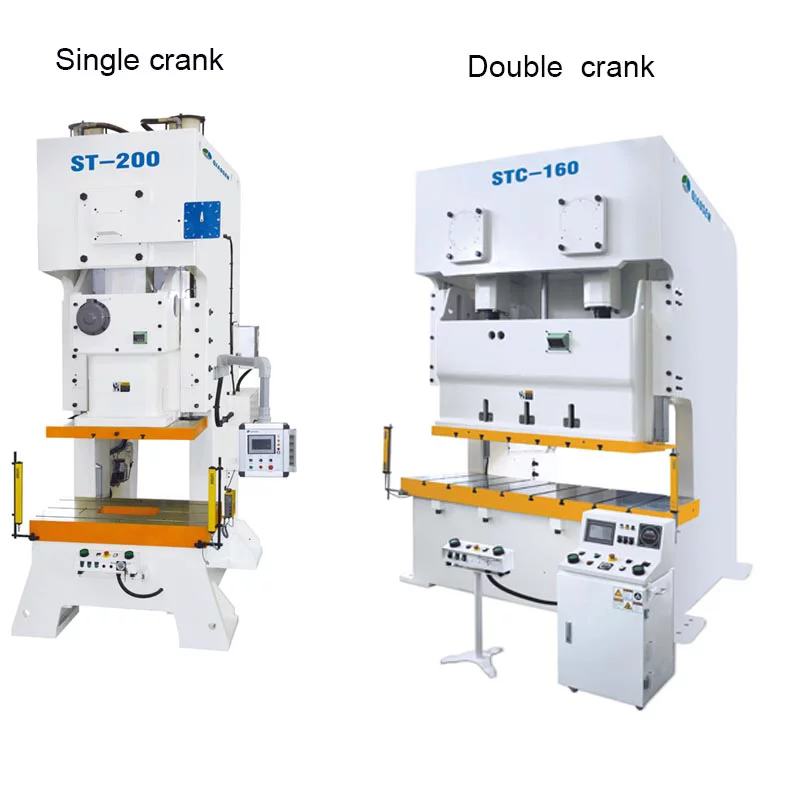

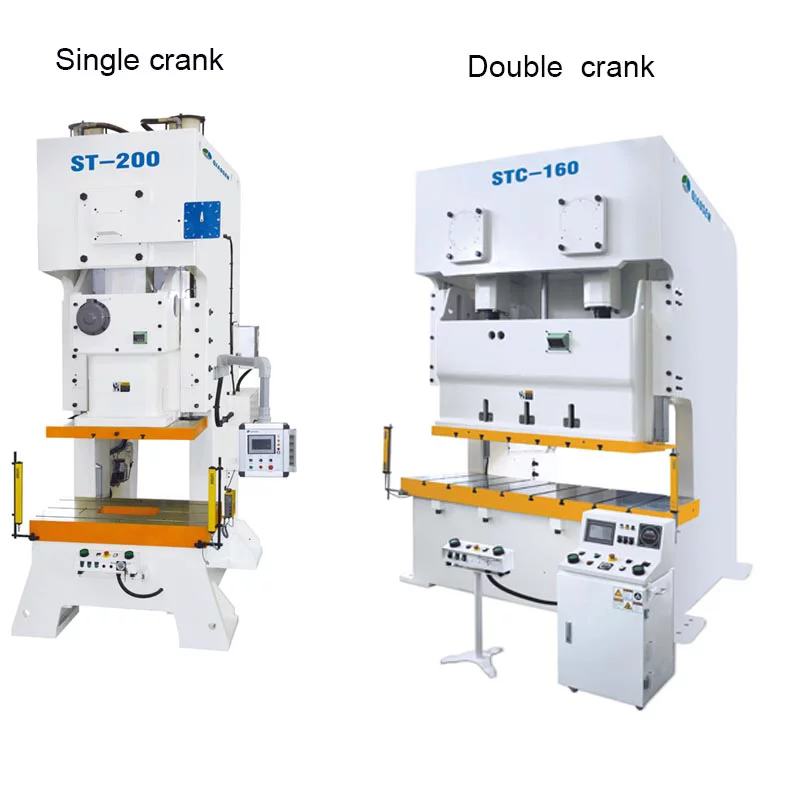

comparation of single crank press and double crank press

1.The Structure of Single-point and Double-point Punch Press

The structure of a single-point punch press is characterized by having only one crankshaft and connecting rod. It has one clutch, while a double-point punch press has two clutches, which results in slightly higher noise levels compared to a single-point press.

On the other hand, a double-point punch press is generally used for high-tonnage applications and has a wider worktable, making it suitable for stamping larger workpieces.

2.The Accuracy and Process of Single-point press and Double-point Punch Press

Compared to single-point punch press, double-point press offers higher precision and allows for higher pressing speeds. It also has less impact on the mold, resulting in significantly improved product quality. However, the price is also higher due to these advantages.

The double-action punch press is designed as an improvement over the traditional single-action punch press. In a traditional single-action punch press, the driving device rotates in a full circle to drive a stamping slide for one reciprocating motion. In contrast, the driving device of a double-action punch press rotates once to drive two slides for simultaneous reciprocating motions. This simplifies the production process and reduces energy consumption.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers