5 Common Problems of High-speed Punch Press Clutches and Solutions

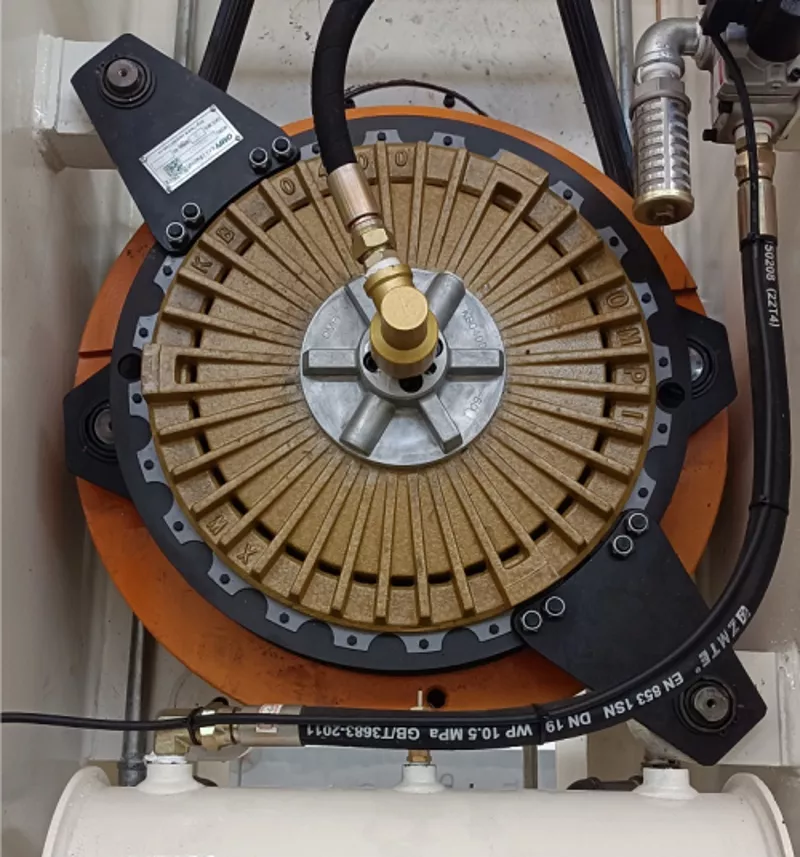

The high-speed punch press clutch is a critical component in the operation of the punch press. It helps to engage and disengage the driving mechanism of the press, allowing for precise control and efficient operation. However, like any mechanical component, the clutch can encounter common issues that may affect its performance. In this article, we will discuss five common problems with the high-speed punch press clutch and their corresponding solutions.

1. Slipping clutch:

A slipping clutch is a common problem that occurs when the clutch fails to engage or disengage properly. This can result in inconsistent strokes, decreased output, and increased wear on the clutch. To resolve this issue, you can try adjusting the clutch engagement mechanism, replacing the friction plates, or cleaning and lubricating the clutch components.

2. Clutch dragging:

Clutch dragging refers to the condition where the clutch remains partially engaged even when it should be fully disengaged. This can cause the machine to continue running even when the operator releases the foot pedal or disengages the clutch lever. To fix this problem, you can check for any binding or misalignment in the clutch linkage, adjust the clutch spring tension, or replace worn-out clutch components.

3. Clutch slipping under load:

Sometimes, the clutch may slip under heavy loads, resulting in decreased power transmission and reduced efficiency. This problem can be caused by worn-out friction plates, insufficient clutch spring tension, or improper lubrication. To solve this issue, you can replace the friction plates, adjust the clutch spring tension, or ensure appropriate lubrication of the clutch components.

4. Clutch chatter:

Clutch chatter is characterized by a repeated jerking or grabbing motion of the clutch during engagement or disengagement. This problem can be caused by misalignment of the clutch components, worn-out friction surfaces, or excessive vibration. To overcome this issue, you can realign the clutch parts, replace the worn-out friction plates or damaged clutch springs, and reduce the machine's vibration by adding dampening measures.

5. Clutch overheating:

Clutch overheating is a common problem that can lead to premature wear, reduced service life, and even failure of the clutch. This issue is typically caused by excessive slippage, inadequate lubrication, or high frictional heat generation. To address this problem, you can adjust the clutch engagement mechanism to minimize slippage, ensure proper lubrication of the clutch components, or install cooling systems to dissipate heat generated during operation.

In conclusion, the high-speed punch press clutch can encounter several common problems that may affect its performance. Slipping clutch, clutch dragging, clutch slipping under load, clutch chatter, and clutch overheating are some of the common issues that can be resolved by adjusting the clutch engagement mechanism, replacing worn-out components, ensuring proper lubrication, and addressing misalignment or excessive vibration. By properly maintaining the clutch and addressing these common problems, the high-speed punch press can operate efficiently and provide reliable performance.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers