How to connect the wires after servo feeder machine arrived at your factory

1. The 1st step is installing the machine on the press machine and adjust the feeding line matched with other

Dive into our Product Knowledge Hub, where our expert sales team shares valuable insights on product knowledge and after-sales service, and more. Gain exclusive access to insider tips and resources to enhance your product ownership experience.

1. The 1st step is installing the machine on the press machine and adjust the feeding line matched with other

The article titled "How to Troubleshoot and Resolve Malfunctions in the Feeder Machine (Part 1)" discusses common issues and their solutions related to Feeder Machines. It covers topics including incorrect material feeding, magnitude and direction of material feeding errors, and sudden malfunctions during the material feeding process. Troubleshooting methods such as increasing pressure, adjusting microswitches, and checking for proper compatibility are provided.

This article provides an overview of the different types of lubricating oils used for QIAOSEN brand presses. Proper lubrication is essential to ensure the press operates smoothly and to extend the lifespan of its components. The article also emphasizes the importance of adhering to strict observation items during maintenance for effective oil supply.

Servo roll feeders are indispensable equipment in modern manufacturing facilities due to their high accuracy and consistency in material feeding. They can be customized to accommodate a wide range of materials.

The choice between a 2in1 metal uncoiling and straightening machine and a metal uncoiling machine should be based on specific requirements and considerations. While the 2in1 uncoiling and straightening machine offers space-saving benefits, time-saving features, and increased precision, it may have limited capacity and higher maintenance needs. On the other hand, the uncoiling machine provides increased capacity, ease of operation, and lower maintenance costs, but may occupy more space and have a longer processing time. Assessing these advantages and disadvantages will help businesses make an informed decision according to their production needs and constraints.

This article provides an overview of a punch feeder, a special conveyor used for conveying granular, powdered, and sheet materials. The punch feeder operates by exerting pressure on the processed material through a die. The hydraulic cylinder gradually increases pressure as the contact time with the working material increases. Once the electromagnetic reversing valve receives a signal, the punching head resets. However, there may be instances where the pressure in the cylinder does not reach the set rated pressure due to time limitations. Nonetheless, the cutting process is completed.

Choosing the right metal punching machine is crucial for businesses to ensure efficiency and avoid wasting their equipment investment. There are several key factors to consider when determining the punching capacity of a press: pressure capacity, torque capacity, and working capacity.

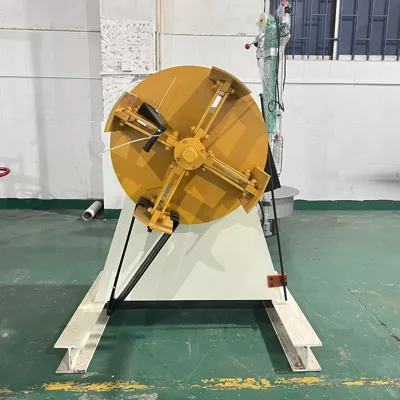

The MT Uncoiler, also known as a decoiler, is a crucial machine in the stamping industry. It is used for continuous stamping of both metal and non-metal coils, making it an indispensable part of any production workshop.Discover the mysteries of uncoilers and boost your stamping production efficiency with the versatile MT Uncoiler machines offered by QIAOSEN machinery.

Pneumatic punch presses are commonly used mechanical equipment in the stamping process. The C-type and H-type pneumatic presses are two common types that differ in configuration and suitability for different stamping products.

When the precision punch is in use, an electric thin oil pump is generally used to drive the lubricating oil i