How to choose the right metal punching machine

Choosing the right metal punching machine is crucial in order to ensure efficiency and avoid wasting equipment investment. There are three main tips for determining the punching capacity of a press: pressure capacity, torque capacity, and working capacity. When selecting a metal punching machine, it is important to correctly determine the processing method and operation method, taking into consideration factors such as production volume, material shape and quality, material handling, and the use of a die buffer. Calculating the processing pressure and pressure stroke curve is also essential in selecting a punching capacity suitable for processing. Additionally, the dimensional accuracy of processed products must be defined based on the use of the product and its connection with the next process. Understanding the function of the press and investigating the specifications of the punch catalog are important steps in choosing the right press. The selection of attachments, flexibility of relevant functions, ease of maintenance, reliability, and security measures are also factors to consider. It is also important to incorporate noise and vibration countermeasures into the stamping equipment in order to comply with regulations and ensure a safe working environment.

Firstly, pressure capacity refers to the maximum force that the press can generate. This is determined by the size and strength of the press's hydraulic system or mechanical components. It is important to determine the required pressure based on the specific production needs of the business.

Secondly, torque capacity refers to the twisting force applied by the press. This is particularly important for applications that involve rotating and bending operations. It is essential to select a press with enough torque capacity to handle the desired operations effectively.

Lastly, working capacity refers to the maximum size and weight of the material that the press can handle. This is determined by the press's bed size and the stroke length. It is crucial to choose a press with sufficient working capacity to accommodate the size and weight of the materials that will be used in production.

When selecting a metal punching machine, it is vital to correctly determine the processing method and operation method. Factors such as production volume, material shape and quality, material handling, and the use of a die buffer should be taken into consideration. These factors will help determine the appropriate press specifications for the desired production needs.

Calculating the processing pressure and pressure stroke curve is also essential in selecting a punching capacity suitable for processing. This involves analyzing the specific application requirements and determining the force and stroke needed to achieve the desired product outcome.

Additionally, the dimensional accuracy of processed products must be defined based on their use and connection with the next process. This ensures that the chosen press can accurately produce parts that meet the required specifications.

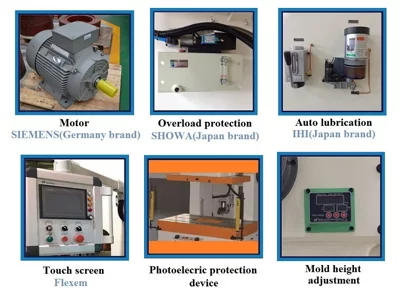

Understanding the function of the press and investigating the specifications of the punch catalog are important steps in choosing the right press. This includes considering the selection of attachments, the flexibility of relevant functions, ease of maintenance, reliability, and security measures.

Furthermore, it is crucial to incorporate noise and vibration countermeasures into the stamping equipment. Compliance with regulations and ensuring a safe working environment should be top priorities. This not only protects the workers but also ensures that the press operates within acceptable noise and vibration limits.

In conclusion, choosing the right metal punching machine involves careful consideration of various factors such as pressure capacity, torque capacity, and working capacity. Determining the processing method, operation method, and dimensional accuracy requirements are also crucial. Additionally, understanding the function of the press, investigating the punch catalog, and considering attachments, flexibility, maintenance, reliability, and security measures are important steps in selecting the appropriate press. Lastly, incorporating noise and vibration countermeasures is essential for compliance and worker safety.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers