How to debug the problem of die jamming in the punch press

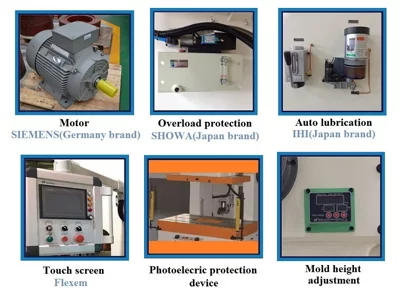

1. Motor debugging method:

1.1For the crankshaft position of the press machine, confirm the bottom dead center or before the bottom dead center.

1.2 Adjust the clutch to 5.5 kg/cm². The motor follows the original slide's bottom dead center. If you see the bottom dead center of the slide, the motor reverses.

1.3 Start the motor starter, let the driven pulley idle and rotate at full speed.

2. Overload oil pump debugging method:

Loosen the screws of the oil pump that is overloaded by the punch, then move the slide to the top dead center and lock it, and you should hear a loud noise. In case of overload, the punch load detection equipment can immediately stop in an emergency to ensure the safety of the mold and stamping.

2.1 Lower the pressure in the oil circuit of the front slide overload safety protection device, and then fix it in place with the bolt.

The motor pulley for perforation starts to idle and moves frequently at full speed.

2.2 Operate the charge and discharge points of the operating switch, operate the button switch. If the clutch is not engaged, it will exceed the load switch, reset the switch position and then repeat the charge and discharge operation button switch to the top dead center position of the slide.

2.3 The upper and lower dies hitting each other will exceed the same overload safety device resetting operation sequence, open the shut-off valve in the pipeline, and normal operation can be carried out.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers