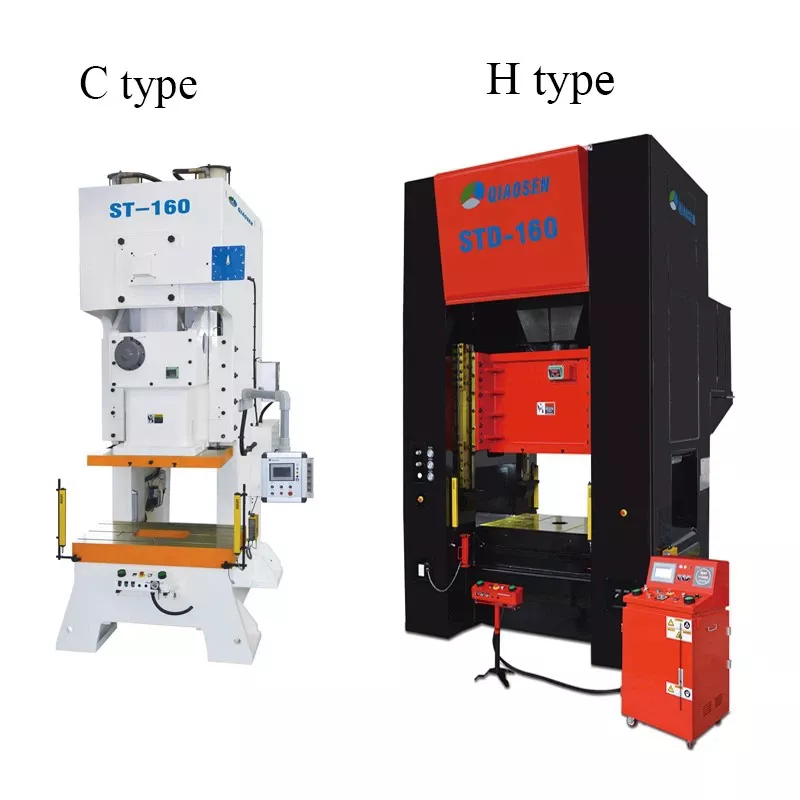

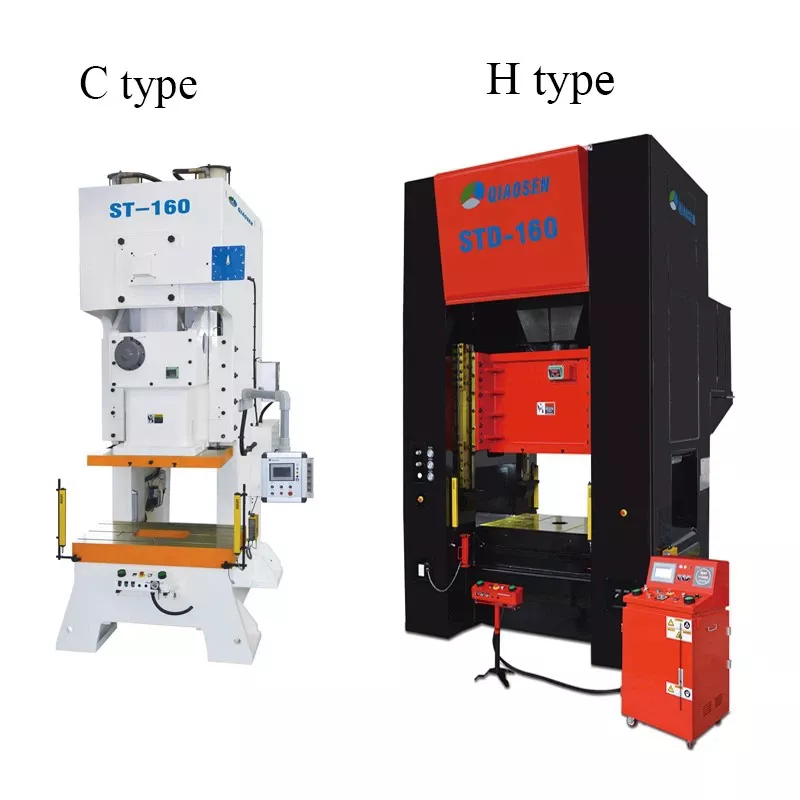

The difference between C-Type Pneumatic Punching Press and H-Type Pneumatic Punching Press

Pneumatic punch presses are commonly used mechanical equipment in the stamping process. The C-type and H-type pneumatic are two common types that differ in configuration and suitability for different stamping products.

Firstly, in terms of configuration, the C-type and H-type pneumatic punch presses have different structures. The C-type press is shaped like a "C" with the base and workbench arranged at a 90-degree angle. On the other hand, the H-type press resembles an "H" shape, offering more stability during stamping compared to the C-type press.

Secondly, in terms of suitability for stamping products, there are differences between the two types. The C-type press is suitable for smaller-sized stamping products, such as punching, stretching, and shearing of small parts. It is compact, small in size, and easy to operate, making it suitable for low-demand stamping product manufacturing.

In contrast, the H-type press is suitable for larger-sized stamping products. Due to its 90-degree arrangement between the base and workbench, the H-type press provides more stability and reliability during stamping. Therefore, it is suitable for stamping processes that require higher rigidity and stability, such as the production of car body parts and automotive components.

Apart from the differences in configuration and suitability, both C-type and H-type pneumatic punch presses share some common features. They both require pneumatic systems to drive the press machine and offer functionalities such as stroke adjustment, pressure adjustment, and speed adjustment. Regular maintenance is also essential for both types to ensure their smooth operation and prolong their lifespan.

In conclusion, C-type and H-type pneumatic punch presses differ in configuration and suitability for different stamping products. The C-type press is suitable for smaller-sized stamping products while the H-type press is suitable for larger-sized products. Choosing the appropriate type of pneumatic punch press can better meet the requirements of various stamping processes, improving production efficiency and product quality.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers