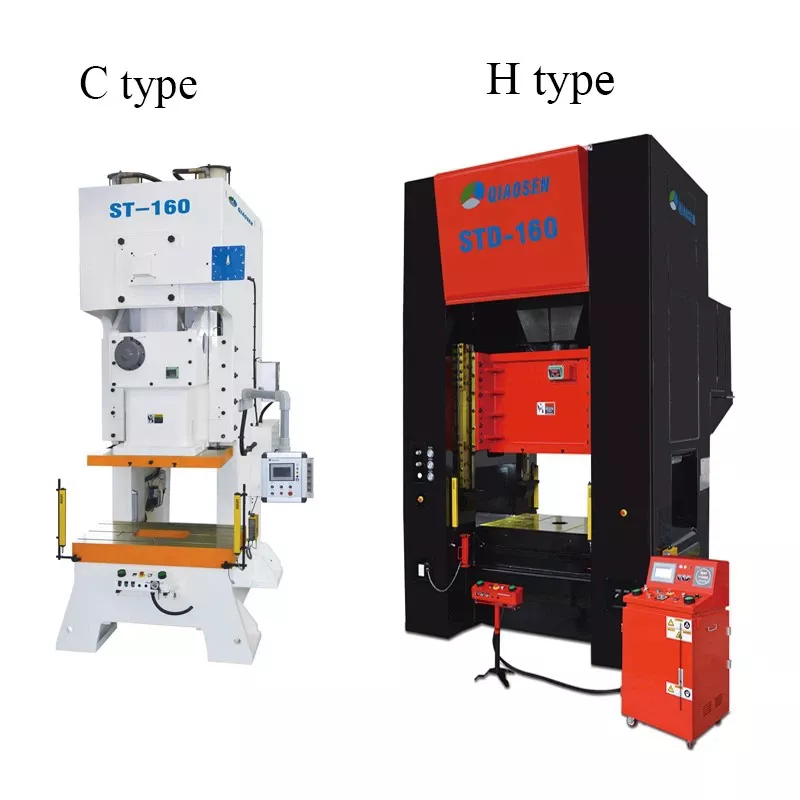

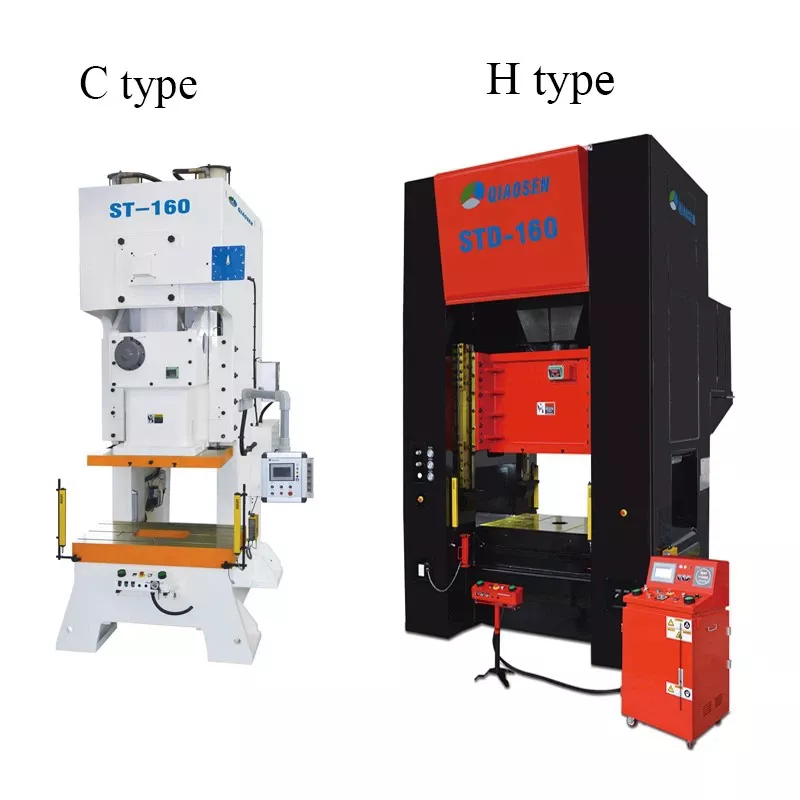

The Diference Between C-Type and H-Type Pneumatic Punch Presses

When it comes to selecting between C-type pneumatic punch presses and H-type pneumatic punch presses, it is important to consider various factors to ensure the best choice is made. These factors include work requirements, processing efficiency, maintenance and cost considerations, and budget constraints.

First and foremost, work requirements must be carefully assessed. This involves determining the thickness and type of materials that need to be processed, as well as the required processing accuracy. Different types of punch presses are suitable for different work requirements. C-type pneumatic punch presses are ideal for processing smaller workpieces, whereas H-type pneumatic punch presses are better suited for larger workpieces.

In addition to work requirements, processing efficiency is another crucial factor. C-type pneumatic punch presses generally have faster working speeds compared to H-type pneumatic punch presses, however, they are limited by their smaller working range. On the other hand, H-type pneumatic punch presses can handle larger workpieces, but their working speed is relatively slower. Therefore, the desired processing efficiency should be taken into account when making a decision.

Maintenance difficulty and cost are also important considerations. C-type pneumatic punch presses have a simpler structure and are, therefore, easier to maintain and have lower maintenance costs. Conversely, H-type pneumatic punch presses have more complex structures, which may result in higher maintenance and repair expenses over time. It is essential to evaluate the long-term maintenance requirements and associated costs before choosing a punch press type.

Lastly, the budget must be considered. C-type pneumatic punch presses are generally more affordable than H-type pneumatic punch presses. Consequently, if budget constraints are a concern, opting for a C-type pneumatic punch press may be the more favorable choice.

To make an informed decision, it is essential to carefully consider all the aforementioned factors. Thoroughly evaluating work requirements, processing efficiency, maintenance and cost considerations, as well as budget constraints, will ultimately lead to the selection of the punch press type that best suits one's needs.

In conclusion, the selection of a punch press type, whether C-type or H-type pneumatic, should be based on a comprehensive analysis of work requirements, processing efficiency, maintenance and cost considerations, and budget constraints. It is imperative to make an informed choice that aligns with specific needs and objectives.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers