Through the observation of the long-term operation of the decoiler, it is found that the original decoiler has complicated installation, complicated pipe installation, serious oil leakage in the pressure chamber and oil return chamber, etc., which is not conducive to improving production efficiency. In response to these problems, several improvements have been made to the structure of the uncoiler, including the improvement of the arc plate and the blocking arm. Through the comparison before and after the improvement, the advantages and significance of the improvement measures are clarified. The improved uncoiler simplifies the processing technology, reduces the cost, and improves the production efficiency. After many practical tests, it has been recognized by users.

Improvement of Arc Plate of Uncoiler

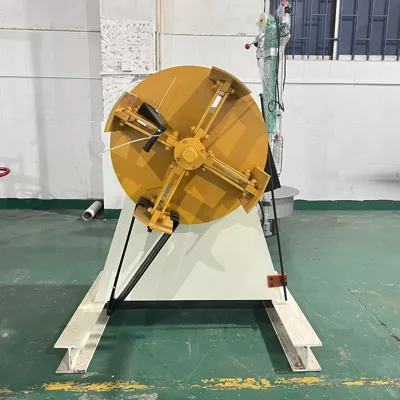

The expansion and contraction drum of the decoiler before the improvement is composed of 4 arc plates, and there are gaps between the arc plates for expansion and contraction. There is a long straight seam between the arc plates of the traditional decoiler. During operation, it is found that due to the large curvature of the steel strip tail, it is often inserted into the gap between the arc plates, hooking the arc plates, causing damage to the equipment.

After the improvement, the arc plate is changed to scraping and staggered arc plate. The arc plates are inserted staggeredly between the arc plates, and the length of the staggered straight seam is less than the minimum width.

Improvement of the stop arm of the uncoiler

A stop arm is installed on the arc plate of the improved front uncoiler to prevent the coil from deviating. The retaining arm of the traditional uncoiler is hooked on the arc plate and can slide on the arc plate to adapt to different coil widths. However, after changing to the scraping staggered arc plate, the blocking arm will have nowhere to hook on the arc plate, and cannot be fixed or slipped, so this kind of blocking arm cannot be used.

After the improvement, the T-bolt structure used in the clamping of the machine tool table is used for reference. Two T-shaped grooves are opened on the arc plate, and the blocking arm and the arc plate are fixed by T-shaped bolts. At the same time, the blocking arm can slide along the T-shaped groove to adapt to different bandwidths. Install and remove the arc plate, that is, loosen the nut one or two buckles and then rotate the T-shaped bolt 90° to remove the stop arm; when installing, insert the T-shaped bolt into the T-shaped slot and tighten the nut. Compared with before the improvement, the structure not only achieves the function of the original blocking arm, but also simplifies the loading and unloading of the blocking arm, which is also proved by practical application.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers