Traditional metal sheets are usually manufactured in the form of coils to reduce space and occupancy area. When used, they need to be unrolled using a material rack before being fed into a leveling machine for processing. Heavy-duty material racks are commonly used in stamping production for feeding and unrolling materials. They control the speed of material feeding through a time relay and automatically adjust the length of the output based on the height of the support rod, ensuring synchronized processing with the subsequent leveling machine. These racks are easy to operate, have a large load capacity, and significantly improve the efficiency of stamping production.

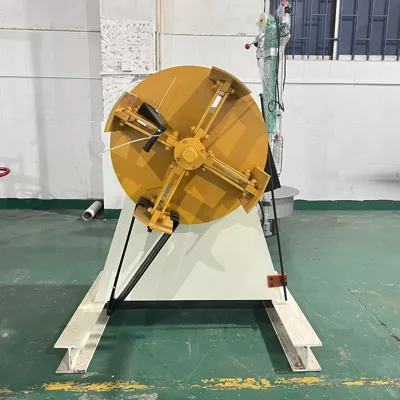

A heavy-duty material rack consists of a frame, a drum, a spindle, an adjustment device, a sliding guide device, a backup wheel, a driving device, and a control box. The cylindrical surface at the left end of the spindle is equipped with an adjustable sleeve and an adjustable screw. The adjustable sleeve slides along the spindle's travel distance, while the adjustable screw with an external screw passes through the spindle's inner hole and connects the adjustable sleeve with a nut. The drum, made of four circular arc material support plates, is connected to the adjustable sleeve on the spindle through a support block, forming a four-link mechanism. Each circular arc material support plate is equipped with a sliding guide device on the right end, which forms a radial sliding fit with the backup wheel, securely connected to the spindle. The spindle, together with the drum, backup wheel, and adjustable screw, is supported by two bearings on the table. The outer cylindrical surface of the spindle, located between the two supporting bearings, is equipped with a sprocket for transferring the winding power. The driving device of the material rack includes a motor and other accessories. The front edge of the frame is also equipped with a sensor device, which is electrically connected to the control box. The sensor device consists of a sensing support rod, a fixed seat, and an edge plate, and is connected to the frame through the sensing support rod.

In actual use, the material rack handle is rotated counterclockwise, causing the axial movement of the adjusting screw and the four-link mechanism connected to the fan-shaped support tile, which reduces the diameter of the drum. The material coil is installed, and the material is tightened by rotating the material rack handle clockwise, completing the feeding of the material. The motor drives the rotation of the coil disc to transport the material, and the material rack is controlled to start or stop by the sensing support rod. The output speed is controlled by the time relay connected to the sensing support rod, while the length of the material is controlled by the height of the sensing rod. When using the heavy-duty material rack for stamping production, operators do not need to constantly control the material transportation, as it operates automatically. It has a compact structure, small footprint, low failure rate, and high reliability, effectively solving the problems of feeding and unrolling in stamping production.

Besides,heavy-duty material racks can be used with a variety of machines, such as shears, hydraulic presses, etc.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers