How to feed metal coils into an automatic stamping line

The automation of the metal stamping process has revolutionized the manufacturing industry, providing increased productivity, efficiency, and accuracy. A crucial aspect of automating metal stamping is the successful feeding of metal coils into the automatic stamping line. This article will discuss the process of feeding metal coils into an automatic stamping line and the machines required to accomplish this task.

Feeding Metal Coils into an Automatic Stamping Line And What Machines Are Required

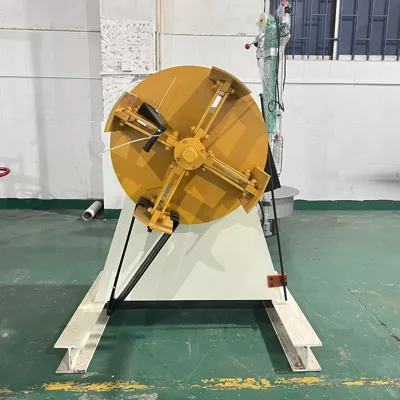

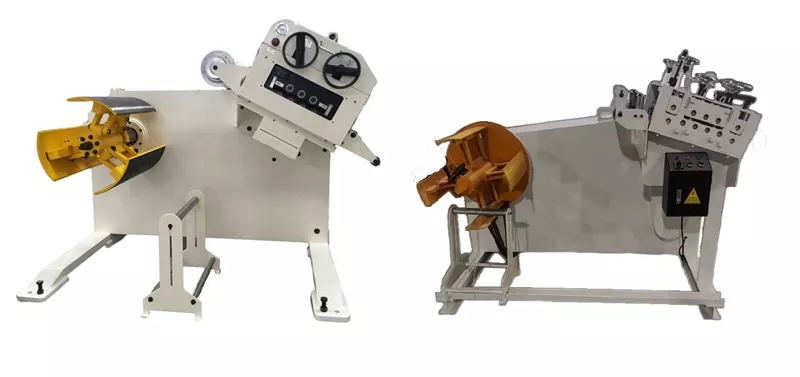

1. Uncoiler Machine:

The uncoiler machine is the first step in the process of feeding metal coils into an automatic stamping line. It is responsible for unwinding the metal coil and providing a continuous feed of metal strip to the subsequent machines. The uncoiler machine consists of a motor-powered mandrel that holds the metal coil, along with a set of rollers that guide the metal strip into the stamping line.

Metal coils often come with inherent distortions and irregularities. The straightener machine is utilized to correct these distortions and ensure a smooth and flat strip of metal is fed into the automatic stamping line. It straightens the metal strip through a set of adjustable rollers that gradually remove any bends or kinks present in the strip.

3. Feeder Machine:

The feeder machine is responsible for accurately and consistently feeding the metal strip into the automatic stamping line. It consists of a driven roller system that grips the metal strip and advances it through the stamping line at a predetermined speed and length. The feeder machine ensures precise positioning of the metal strip for precise stamping operations.

4. Progressive Die Machine:

The progressive die machine is an essential component of an automatic stamping line. It utilizes a series of customized cutting and forming dies that progressively shape the metal strip as it moves through the machine. The progressive die machine performs multiple stamping operations in a single pass, such as blanking, bending, and punching, ensuring high productivity and efficiency.

Conclusion

Feeding metal coils into an automatic stamping line requires a well-coordinated integration of specialized machines. The uncoiler machine unwinds the metal coil, the straightener machine corrects any distortions, the feeder machine accurately feeds the metal strip, and the progressive die machine performs a series of stamping operations. This seamless process ensures a continuous and efficient production of stamped metal parts. By automating the feeding process and utilizing these specific machines, manufacturers can achieve higher productivity, increased efficiency, and improved quality in their metal stamping operations.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers