7 ways to reduce power press punch noise

1. In order to reduce the sound source noise, the overall structure of the press machine workshop was modified into a so

Dive into our Product Knowledge Hub, where our expert sales team shares valuable insights on product knowledge and after-sales service, and more. Gain exclusive access to insider tips and resources to enhance your product ownership experience.

1. In order to reduce the sound source noise, the overall structure of the press machine workshop was modified into a so

There are many types of punch presses, and their protective devices also come in many forms. The protective devices of punch machines can be mainly divided into the following two types.

Aluminum foil capsules for coffee cups have several advantages over plastic coffee capsule cups. First, aluminum foil is a better barrier against oxygen, light, and moisture, ensuring the freshness and flavor of the coffee for a longer time compared to plastic which is more permeable. Second, aluminum foil is a better conductor of heat, allowing for a more efficient and even distribution of heat during the brewing process. Third, aluminum foil is a more eco-friendly option as it is easily recyclable, whereas plastic capsules are often not recyclable and contribute to plastic waste.

A pneumatic punch press primarily derives its power from compressed air, making it a versatile and efficient machine for various industrial processes. It is commonly used for cutting, piercing, stamping, and forming operations in industries such as automotive, electrical, and metal fabrication. The underlying principle of the pneumatic punch press lies in converting energy from compressed air into mechanical force, allowing it to perform a wide range of tasks with precision. A pneumatic punch press consists of several essential components that work in tandem to produce the desired output. Let us delve into the intricacies of these components.

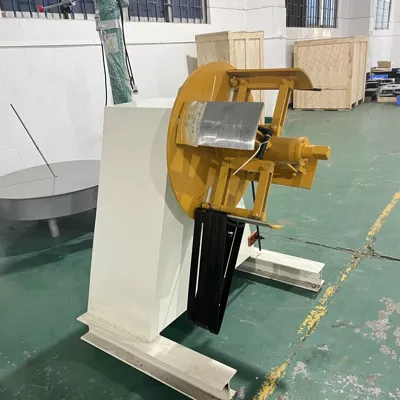

The steel decoiler machine is a highly advanced industrial machinery that consists of six essential components: a strong base, a secure support frame, a flexible expansion and contraction system, a efficient drive mechanism, an advanced electrical control box, and a precise sensor.

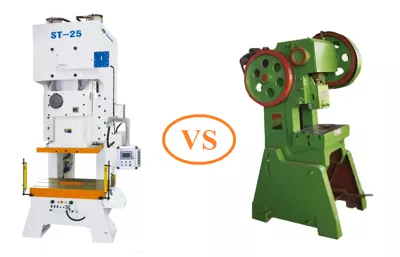

As we all know, compared with traditional mechanical processing, the stamping process of open punch presses saves materi

In the field of metalworking, two commonly used machines for punching holes and shaping metal sheets are the pneumatic punch press and the hydraulic punch press. Although both machines serve similar purposes, they differ in their underlying mechanisms, performance, and applications. This article aims to explore the main differences between pneumatic punch presses and hydraulic punch presses, covering their working principles, advantages, disadvantages, and suitable applications.

Punch press workers must learn, master the structure and performance of the punch press, be familiar with the operating procedures and obtain an operating license before they can operate independently.

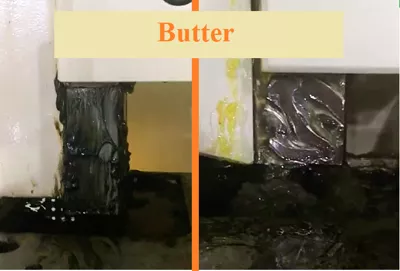

When a punch press butter turns black after use, it could indicate potential issues with the lubrication process or other underlying problems. The phenomenon of punch press butter turning black can have multiple implications, including

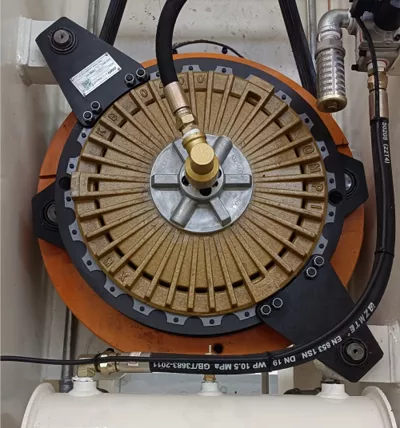

The clutch is an important component of a pneumatic punch. The pneumatic friction clutch used in the punch is generally divided into two types: wet clutch and dry clutch.