The Difference between Pneumatic Punch Dry Clutch and Wet Clutch

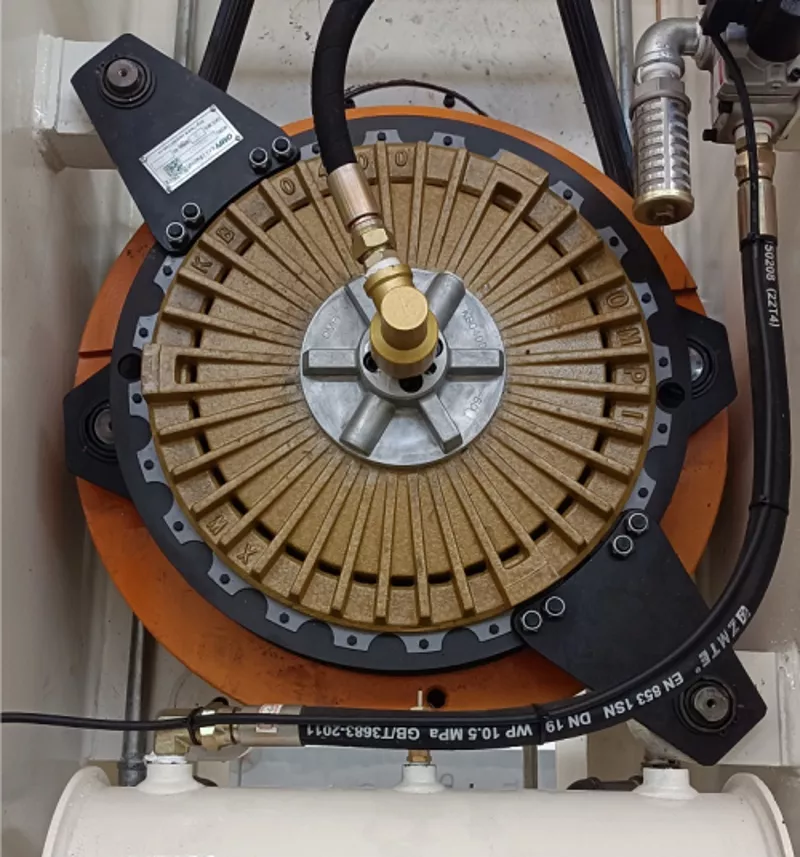

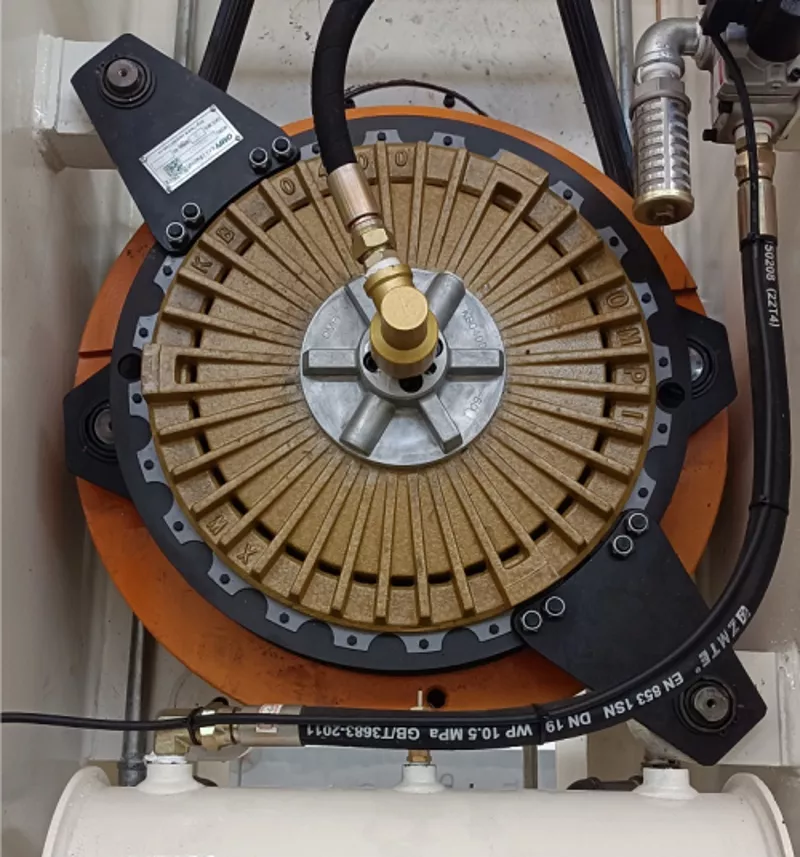

The clutch is an important component of a pneumatic punch. The pneumatic friction clutch used in the punch is generally divided into two types: wet clutch and dry clutch.

The wet clutch contains hydraulic oil, and the friction plate connects and disengages in the oil film under the pressure of air. On the other hand, the dry clutch does not contain hydraulic oil, and instead, it relies on air pressure to connect and disengage the friction.

The wet clutch can theoretically be wear-free due to the presence of the oil film. In contrast, the dry clutch wears out with each engagement. Therefore, the friction plate has a limited lifespan. However, it is worth noting that the quality of wet clutches is currently not as stable as that of dry clutches. As a result, wet clutches are more commonly used in small-tonnage punches, while dry clutches are still more prevalent, especially in large-tonnage punches (especially closed-type punches).

In conclusion, there are distinct differences between the wet clutch and dry clutch used in pneumatic punching machine. The choice of which type to use depends on factors such as tonnage and the specific requirements of the metal stamping machine.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers