What's The Difference Of C Type Press Machine And H Type Press Machine?

The open crank press machine, often referred to as a crank press, is a type of mechanical forging machine. It operates by transmitting the motion and energy of a motor through a transmission system to the working mechanism, allowing the blank to take on a specific shape.

The main components of an open press include the body, working table, rod seat, bearing seat, copper bushing, and left and right guide rails. The body is typically made of cast iron or welded steel plate. The working table features a circular blanking hole for easy blanking. The table can be attached and detached as needed. The slider is fixed within the V-shaped guide rails on both sides of the body, and the gap between the rail and slider can be adjusted using screws. During operation, the beating screw strikes the horizontal beating rod within the slider, functioning as a rigid pusher. The position of the rod screw can be adjusted accordingly.

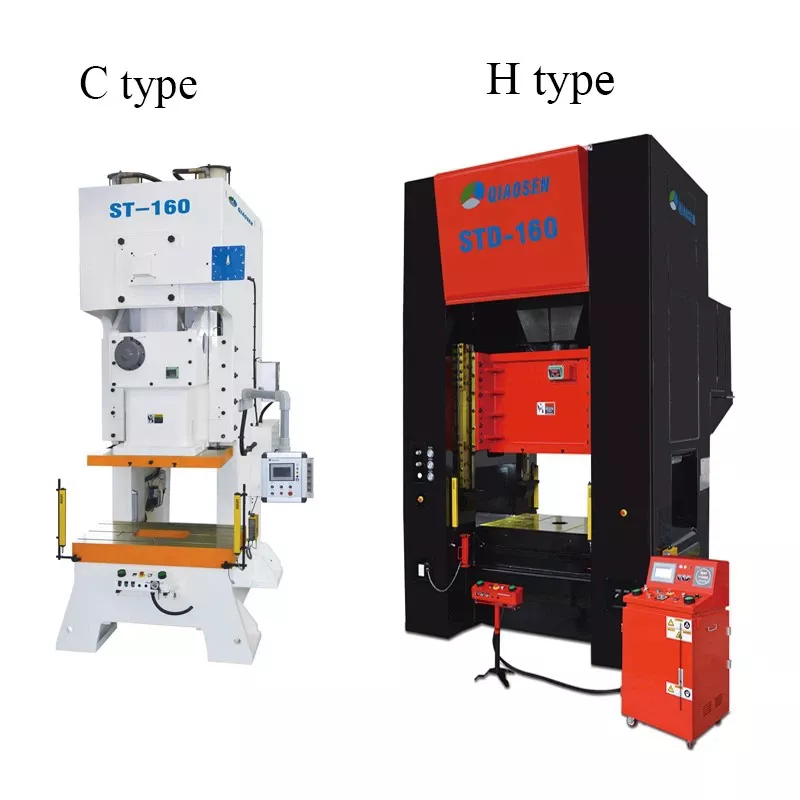

The open press machine differs from a closed press machine in two main aspects. Firstly, in terms of appearance, the open type has three sides open – the front, left, and right – allowing for feeding from multiple directions. It adopts a C-shaped structure, while the closed type only has front and rear openings for material feeding. Its structure consists of slider guide rails and machine tool columns at all four corners.

Secondly, in terms of performance, the open type tends to have lower rigidity compared to the closed type due to its C-shaped structure. As a result, it is more susceptible to vibrations during operation, leading to lower precision. For this reason, large-tonnage stamping machine tools, typically above 400T (though rare for anything over 200T), mostly adopt the closed type structure, as it offers better stability and precision.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers