The introduction of 2 in 1 decoiler and straightener

Explore our range of specialized machinery solutions designed to optimize production efficiency and meet the demands of various applications. From coil straightening to decoiling machines and more, our products are engineered with precision and durability in mind. Discover how our advanced features can provide a stable processing platform and streamline your production processes.

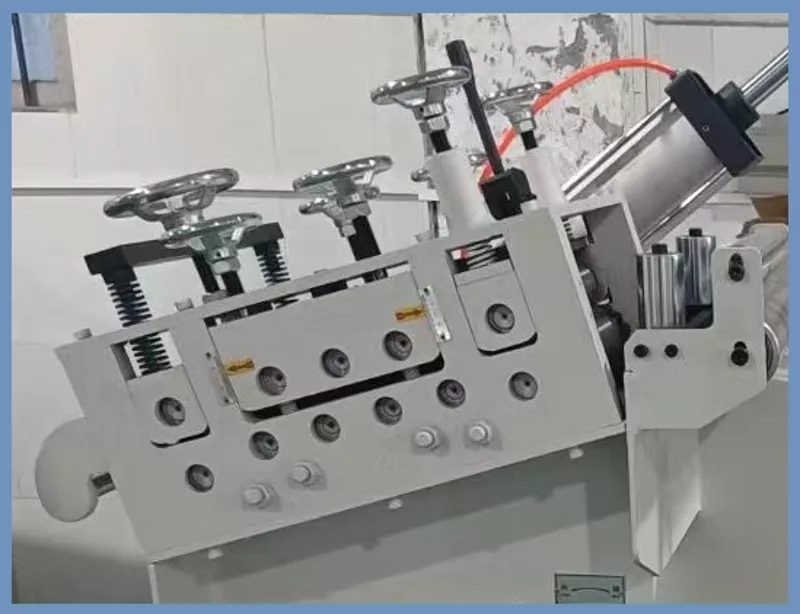

2 in 1 decoiler and straightener

The 2 in 1 decoiler and straightener is a versatile piece of equipment that combines the functionalities of a decoiling machine and a metal straightening machinery. This article will focus on the four key components of this machine and highlight their professional features.

Starting with the decoiling machine, it comes with the option of single-end or double-ended configurations. By providing double-ended configurations, the machine aims to optimize production efficiency by minimizing the coil changeover time. Moreover, the machine offers traveling reels that can be combined with automatic centering functions, further enhancing its efficiency. Additionally, custom engineering is available to tailor the machine to specific application demands, ensuring maximum versatility and usability.

Moving on to the metal straightening machinery, it adopts a parallel roller design with three rollers placed above and four rollers placed below, totaling seven rollers. This configuration ensures effective and precise straightening of metal materials. Furthermore, the machine incorporates a four-point fine adjustment system, making it suitable for processing high-precision products. The four-point independent pressure adjustment feature in the feeding roller helps to prevent material deviation and deformation, guaranteeing optimal results.

The electric control box of the 2 in 1 decoiler and straightener is designed with professionalism in mind. It utilizes silver alloy relays and full copper coils for enhanced durability. The flame retardant safety base ensures safety in operation. The inclusion of safety protection adjustment circuit time delay relay and silver alloy contacts caters to different delay range requirements. Additionally, the self-duplex flat button offers light force, moderate key range, and a building block type combination structure. The contact points, made of keto-base composite material, exhibit strong conductivity and large current carrying capacity for up to 1 million times of usage.

Finally, the product bracket shell is constructed to provide a highly rigid structure. Its surface hardness of HRC60, combined with chrome plating, ensures durability and resistance to wear and tear. The design of the bracket shell aims to provide a stable processing platform for optimal performance.

In conclusion, the 2 in 1 decoiler and straightener incorporates a decoiling machine and a metal straightening machinery, resulting in a versatile and professional piece of equipment. Each of its four key components offers unique features and functionalities that enhance productivity, precision, safety, and durability. Whether it is for standard applications or specific customer demands, the machine is designed to meet the utmost requirements and deliver exceptional results.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers