The heavy-duty material rack is an essential peripheral equipment used in the automation of various processing machines such as punching machines, hydraulic presses, shearing machines, laser cutting machines, and forming machines. Its primary function is to facilitate the unwinding or rewinding of coils.

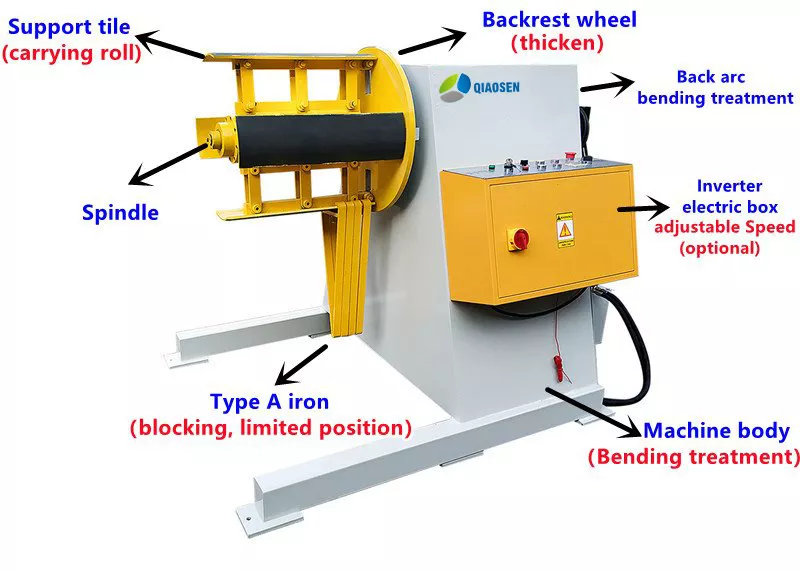

The uncoiler is constructed with the following components: the main body, main shaft, supporting tiles, induction control rod, A-type iron, and electric control box.

1. The bottom of the main body is equipped with a bottom plate, which is fixed with a support frame. The support frame consists of two sets of standard H-shaped steel feet.

2. On the side of the main body, an electric control box is installed, housing a motor. The electric control box enables easy control of the equipment, and a rubber shock pad is placed beneath the motor for vibration isolation.

3.A reducer is installed at the output end of the motor, and a main shaft extends externally from the reducer.

4.The end of the main shaft close to the main body is fitted with a back wheel, while the opposite end of the main shaft is connected to a hand crank through a main shaft sleeve. The hand crank is designed with a non-slip handle.

5.The main shaft is equipped with four evenly spaced support rods on its side. These support rods are fitted with heavy-duty material support pads, which allow for adjusting the diameter of the wound material. The outer surface of these support pads is coated with a wear-resistant non-slip material, ensuring they can handle heavy-duty materials.

6.An induction control rod is installed on the outer side wall of the bottom of the main body through the edge plate.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers