Structure and Classification of Punching Press Molds

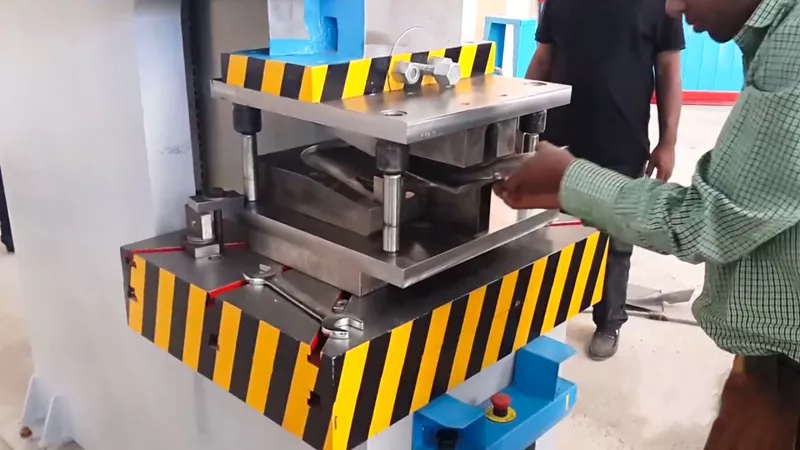

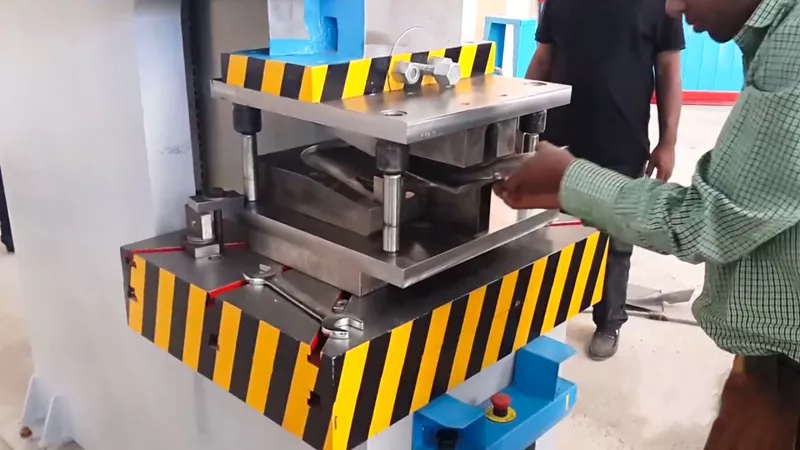

Punching press molds are specialized tools used on punching presses for metal sheet stamping processes. The design and selection of punching press mold structures have a significant impact on product quality and production efficiency. The structure of punching press molds typically includes several main components such as the lower die base, upper die base, guiding components, and fixing components.

First, let's discuss the lower die base. The lower die base is a part of the punching press mold and is usually composed of a base, backing plate, and lower die. The lower die base often needs to bear a large amount of lateral loads, so it typically employs high-precision guiding components and is directly fixed to the mold base. The structural design should have sufficient strength and rigidity to ensure stability during the operation of the mold.

Next is the upper die base, which is similar to the lower die base but simpler. The upper die base usually consists of a top plate and upper die. The top plate is used to fix the upper die and can also be used to adjust the mold height to accommodate different work piece thicknesses. The upper die base often includes spring components to provide appropriate pressure and rebound force. The structural design of the upper die base should consider strength, stability, and ease of adjustment.

Guiding components are important parts of the punching press mold structure, ensuring accurate movement direction and distance between the upper and lower dies. Guiding components typically include guide posts, guide sleeves, and guide pins. The design of guiding components should meet requirements for stability, wear resistance, and sliding performance to ensure smooth operation of the mold.

Lastly, the fixing components are used to secure various parts of the punching press mold. Fixing components commonly include bolts, washers, and nuts. The selection and design of fixing components should consider the safety and convenience of mold operation.

In conclusion, the structure of punching press molds mainly consists of the lower die base, upper die base, guiding components, and fixing components. The structural design of each component should consider factors such as stability, rigidity, adjustability, and wear resistance to ensure stable operation and efficient production of the punching press mold.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers