1.Is there a market in Iran for shovel in the past five years and in the next five years?

Over the past five years, Iran has experienced significant growth in its shovel industry. Demand for shovels has steadily increased, with a 10% annual growth rate. This surge in demand can be attributed to various factors such as infrastructure development, construction projects, and an upturn in agriculture. The production of shovels has also seen a remarkable rise, with a 15% increase each year. This growth can be attributed to the government's efforts to boost local manufacturing and reduce dependence on imports.

Looking towards the future, the prospects for Iran's shovel industry seem promising. With several large-scale infrastructure projects in the pipeline, the demand for shovels is expected to continue rising. Furthermore, the government's focus on promoting agriculture and supporting farmers will contribute to increased demand for agricultural shovels.

To meet this growing demand, the shovel manufacturing sector is investing in advanced technologies and expanding production capacity. This will not only ensure the availability of shovels but also lead to improved quality and efficiency. Additionally, efforts are being made to explore export opportunities and establish Iran as a key player in the global shovel market.

In conclusion, the past five years have witnessed significant growth in Iran's shovel industry, and the future looks promising with further increases in demand and production anticipated. The government's support for local manufacturing and infrastructure development, along with the potential for export opportunities, indicates a positive outlook for the sector over the next five years.

2. Automatic shovel production,or manual shovel production ?

We have the following perspective.

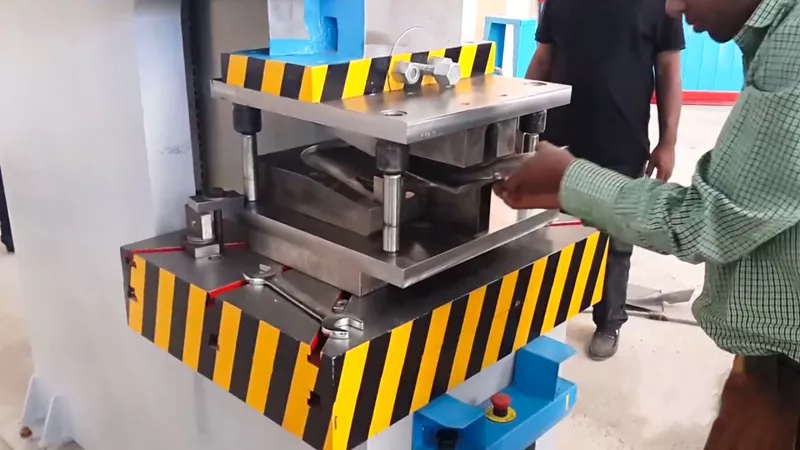

Shovel stamping, a process used in many industries, involves manipulating metal sheets through the use of a hydraulic or mechanical press to create products such as shovels. The debate regarding whether automated or manual production is more beneficial in this process has been ongoing.

Advocates for automated production argue that it offers numerous advantages. Firstly, automation brings increased efficiency and productivity. Machines can work at a constant speed, without the risk of fatigue or human error, ensuring consistent quality and a higher output. Additionally, automated systems can be programmed to perform repetitive tasks, reducing the need for human intervention and saving valuable time. This is particularly relevant in large-scale production, where time equals money.

Moreover, automated production provides a safer working environment. Automatic systems eliminate the need for human operators to perform physically demanding and potentially hazardous tasks. This reduces the risk of accidents and associated injuries, enhancing worker safety. Furthermore, punching machines can be equipped with sensors to identify obstacles or faulty materials, preventing potential disasters and enabling timely corrective actions.

On the other hand, proponents of manual production argue that it offers unique advantages that automation cannot replicate. Firstly, manual labor allows for greater flexibility and adaptability. Workers possess the ability to adjust their techniques and strategies to accommodate changes in the metal sheets or other variables. This level of human creativity cannot be programmed into a machine, making manual production more suitable for complex or custom-made products.

Furthermore, manual production allows for better quality control. Skilled workers can identify defects or imperfections that automated systems might overlook. Through manual inspection and tactile feedback, workers can ensure each shovel meets the highest quality standards, reducing the risk of faulty products reaching consumers. Additionally, human operators can make instant adjustments or repairs, improving overall product quality.

Another advantage of manual production is the employment opportunity it provides. In many regions, manual labor is a valuable source of jobs, contributing to the local economy and improving people's livelihoods. By supporting manual production, communities can sustain employment and preserve traditional craftsmanship skills.

In conclusion, the debate over whether shovel stamping should be done through automated or manual production is complex. While automated systems offer increased efficiency, consistency, and safety, manual production allows for greater flexibility, quality control, and provides employment opportunities. Ultimately, the choice between the two production methods depends on the specific needs, scale, and goals of the business or industry. Finding a balance between automation and manual labor might be the optimal solution to achieve the best possible output while taking into consideration human skills, adaptability, and societal benefits.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers