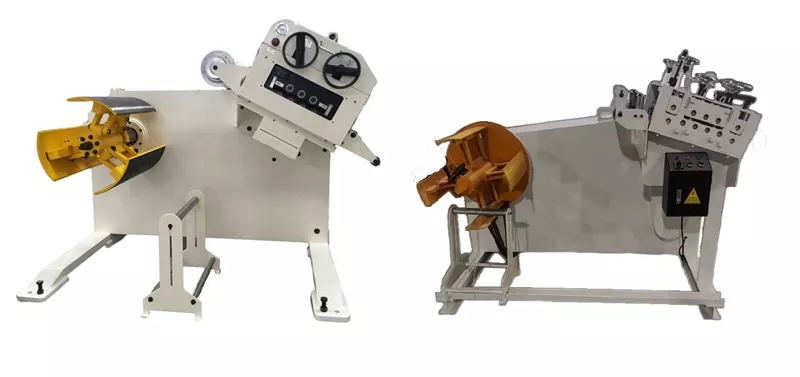

2 in 1 Metal Uncoiling and Straightening Machine or Metal Uncoiling Machine

In the metal working industry, the use of machines is crucial to ensure efficiency and precision. Two important machines used in metalworking are the 2 in 1 metal uncoiling and straightening machine, also known as the metal two-in-one straightening machine, and the metal uncoiling machine. While both machines serve similar purposes, they have distinct advantages and disadvantages that need to be considered before making a choice.

●Advantages of the 2 in 1 Metal uncoiling and straightening machine:

1. Space-saving:

The 2 in 1 metal uncoiling and straightening machine combines the functions of both straightening and uncoiling into a single unit. This helps save valuable floor space in the workshop, making it more efficient for smaller and crowded workplaces.

2. Time-saving:

With the ability to perform straightening and uncoiling simultaneously, this machine significantly reduces the overall processing time. It eliminates the need for separate operations, streamlining the workflow and enhancing productivity.

3. Precision and accuracy:

The 2 in 1 uncoiling and straightening machine is equipped with advanced technology, such as sensors and automated controls, to ensure precise and accurate material straightening and uncoiling. This enhances the quality of the end product and reduces the chances of errors.

●Disadvantages of the 2 in 1 metal uncoiling and straightening machine:

1. Limited capacity:

Due to the combination of two functions in a single machine, the capacity of the 2 in 1 metal uncoiling and straightening machine may not match that of specialized machines. In cases where large quantities or heavy-duty materials need to be processed, a separate uncoiling machine may be a more suitable option.

2. Maintenance and repair:

As a complex machine with multiple functionalities, the 2 in 1 metal uncoiling and straightening machine may require more frequent maintenance and repairs compared to single-purpose machines. The need for specialized technicians to handle any issues may also pose challenges.

●Advantages of the Metal Uncoiling Machine:

1. Increased capacity:

The metal uncoiling machine is designed specifically for uncoiling metal coils. As a result, it typically has a higher capacity to handle larger and heavier coils compared to the 2 in 1 uncoiling and straightening machine.

2. Ease of operation:

Since the metal uncoiling machine is focused solely on the uncoiling process, it is often simpler and easier to operate. This reduces the training time required for operators and minimizes the chance of errors during operation.

3. Lower maintenance cost:

With a single functionality, the metal uncoiling machine generally has lower maintenance and repair costs compared to the multi functional 2 in 1 uncoiling and straightening machine. Additionally, its simpler design may make it easier to access and fix any issues that arise.

●Disadvantages of the Metal Uncoiling Machine:

1. Occupies more space:

The need for separate machines for straightening and uncoiling means that the metal uncoiling machine alone takes up more space than the 2 in 1 uncoiling and straightening machine. This may be a challenge for smaller workshops or factories with limited floor space.

2. Longer processing time:

As the metal uncoiling machine performs only the uncoiling function, it requires additional time for the subsequent straightening process. This can lead to increased processing time and may not be suitable for situations that demand quick turnaround.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers