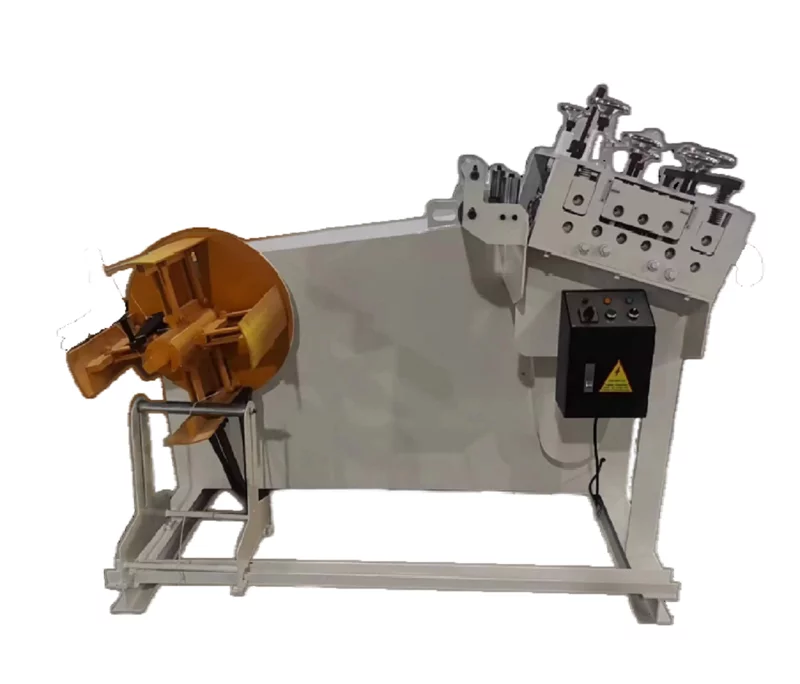

GO 2-in-1 straightening and uncoiling machine

Basic Attributes

- Coil Width 200-700 mm

- Coil Thickness 0.3-3.2 mm

- Feeding Speed 16 m/min

- Model GO

Product Overview

GO series 2-in-1 straightening and uncoiling machine is suitable for the production process of various metal and non-metal materials, efficiently uncoiling the material while simultaneously straightening it. This machine is a device that integrates straightening and uncoiling functions, and its design enhances space utilization in the production line, providing a more efficient use of space along with a simplified operation and installation process.

●Wide Range:

Suitable for collecting and delivering various coil materials, including thin metal and non-metal materials.

●Motor Power Addition:

Motor power can be added to match the feeding device.

●Stability:

The tension of the brake device is adjustable, and the reinforced main shaft ensures smooth rotation of the material reel, increasing the load force.

●Space Efficiency and Error Reduction:

The straightener is integrated with the uncoiler, saving space and reducing the usual error in feeding and overall demand for accuracy, making installation easier.

●Imported Parts:

Utilizes imported parts, resulting in fewer failures and a longer lifetime.

Product Specifications

| Item name | Unit | GO200 | GO300 | GO400 | GO500 | GO600 | GO700 |

| Material width | mm | 200 | 300 | 400 | 500 | 600 | 700 |

| Leveling thickness | mm | 0.5-3.2 | 0.5-3.2 | 0.5-3.2 | 0.5-3.2 | 0.5-3.2 | 0.5-3.2 |

| Material diameter | mm | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 |

| Material outer diameter | mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Material weight | kg | 800 | 1000 | 1200 | 2000 | 2500 | 2500 |

| Correction speed | m/min | 15 | 15 | 15 | 15 | 15 | 15 |

| Motor | HP | 1 | 2 | 2 | 3 | 3 | 3 |

| Expansion method | - | Manual | |||||

| Machine weight | kg | 1000 | 1100 | 1200 | 1400 | 1600 | 1800 |

| Machine dimension(L*W*H) | - | 2000*1400*1400 | 2100*1500*1500 | 2200*1600*1600 | 2300*1700*1700 | 2400*1800*1800 | 2500*1900*1900 |

Product Details

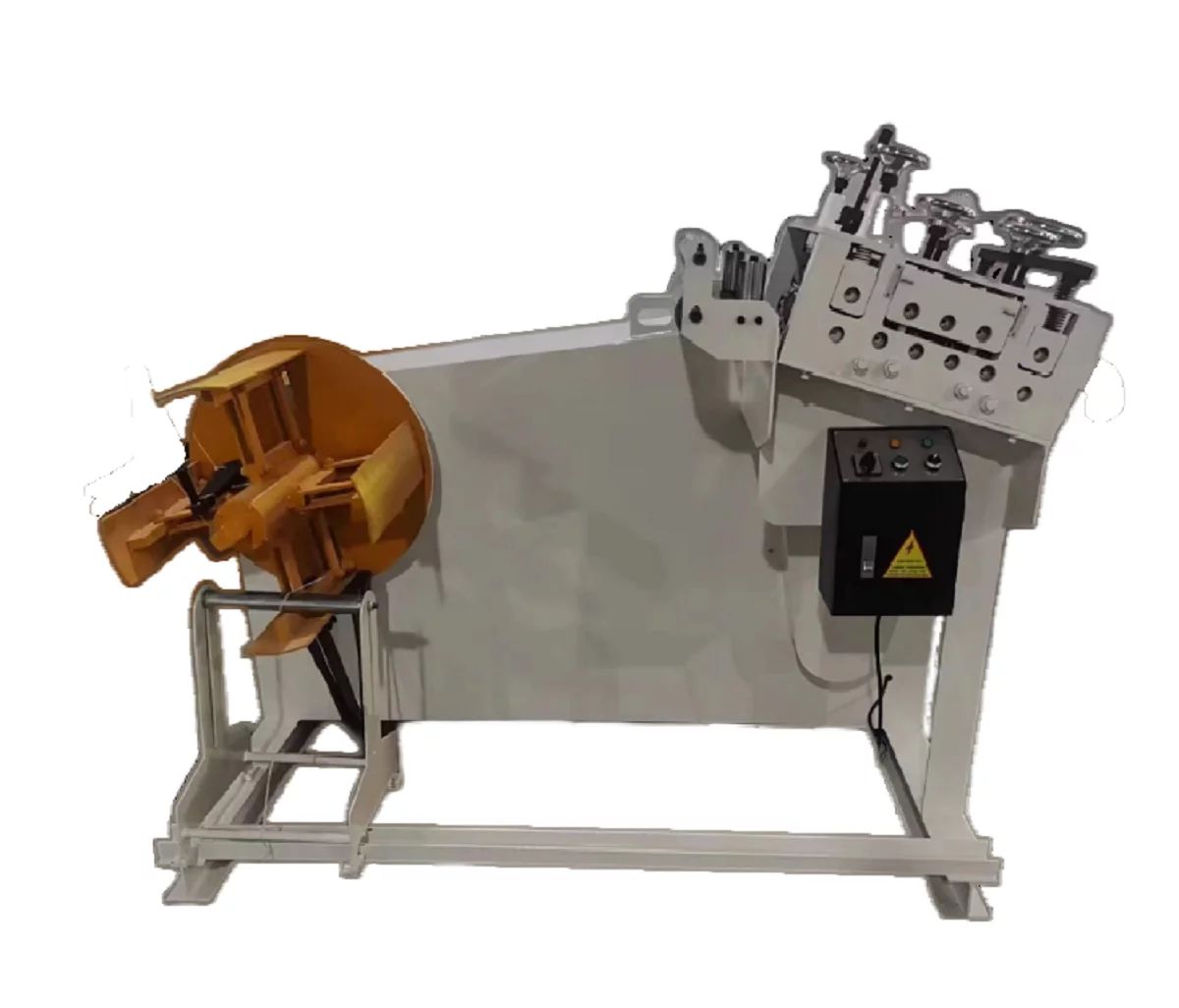

1. Metal Straightening Machine:

●Standard single-end configurations provided; double-ended configurations available for increased production efficiency by reducing coil changeover time.

●Many models available as Traveling Reels, which can be combined with automatic centering functions.

●Custom engineering services offered to meet specific application requirements.

2. Decoiling Machine:

●Standard single-end configurations provided; double-ended configurations available for increased production efficiency by reducing coil changeover time.

●Many models available as Traveling Reels, which can be combined with automatic centering functions.

●Custom engineering services offered to meet specific application requirements.

3. Electric Control Box:

●Utilizes silver alloy relay and full copper coil for durability.

●Flame retardant safety base ensures safety.

●Safety protection adjustment circuit includes time delay, silver alloy contact, various and dial settings to satisfy different delay ranges.

●Switch with sliding contact, self-cleaning function, separate bonding structure for normally open and normally closed contacts, anti-rotation positioning, and stop loose mounting gasket.

●Features a user-friendly control panel for easy operation, reducing downtime.

4. Product Bracket Shell:

●Surface hardness of HRC60 with chrome plating.

●Highly rigid structure and design provide a stable processing platform.

5. Pneumatic Press Arm (Optional):

●The pneumatic press arm maintains pressure on the sheet metal during feeding, preventing coil loosening.

●The press arm's wheel is coated with PU to avoid scratching the surface of the metal strip.