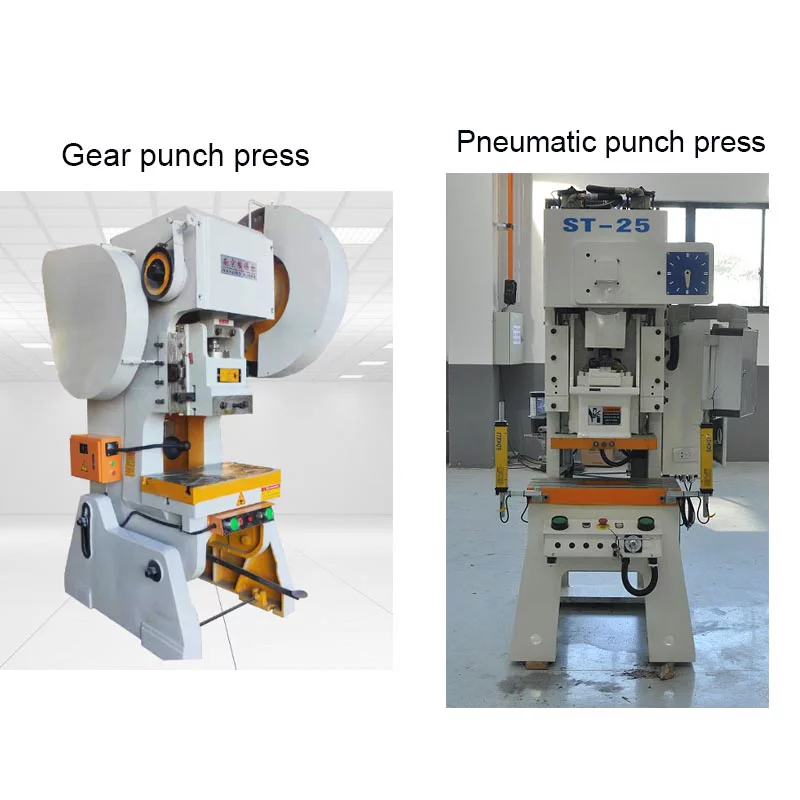

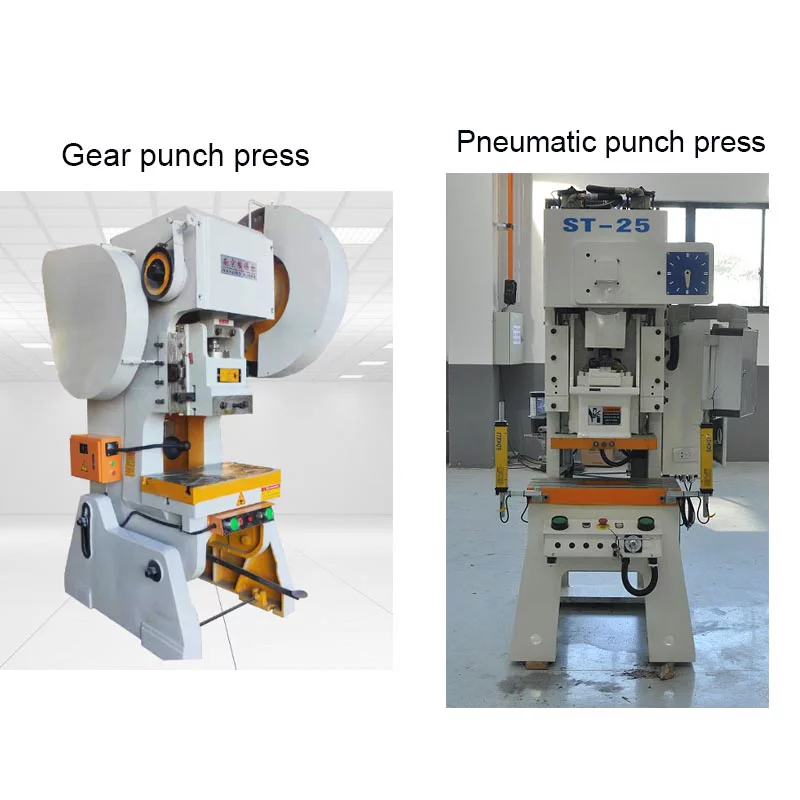

Whats the difference between gear press and pneumatic punch press

Mechanical punch presses are mainly divided into traditional gear punch presses and high-performance pneumatic punch presses. What are the differences between the two punch machines, which one is more economical, which one is safer, and how to choose the type of punch machine that suits you? With everyone’s questions, this article will introduce the differences between the two. Of course, with the advancement of technology, servo punching machines have slowly entered people's field of vision, but their popularity is not yet high.

1. Different braking methods

The biggest difference between gear punches and high-performance pneumatic punches is the different braking methods: gear punches use rigid key brakes, and the slider and crankshaft can only stop at the top dead center position; high-performance pneumatic punches use pneumatic clutch brakes, sliding The block and crankshaft can be parked in either position.

2. Different environmental requirements

Small-tonnage gear punches are operated by foot-operated mechanical pull rods. Some large-tonnage gear punches use electromagnetic clutches, so they only need power to start. Because high-performance pneumatic punch presses use pneumatic clutches, the working environment must have an air source.

3. Different accuracy

Gear punches use dovetail guide rails; high-performance pneumatic punch presses generally use C-type guide rails, which have higher precision and better stability.

4. Different overload methods

Gear punches use a steel safety block overload method. Once overloaded, the safety block will break and need to be replaced. Most high-performance pneumatic punches use a hydraulic overload method. After overload, the hydraulic oil in the overload cylinder will flow back to the mailbox. , the overloaded pump can be reused after pressurization without replacement.

5. Different input costs

Precisely because the structure of the gear punch machine is relatively simple, the price of the gear punch machine is relatively favorable, which is suitable for small businesses that have just started a business and some products with low precision requirements; high-performance pneumatic punch machines often cost tens of thousands or even hundreds of thousands, and the investment is The cost is relatively large. Although the quality of high-performance pneumatic punches is relatively reliable, once a failure occurs, the maintenance cost is relatively high.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers