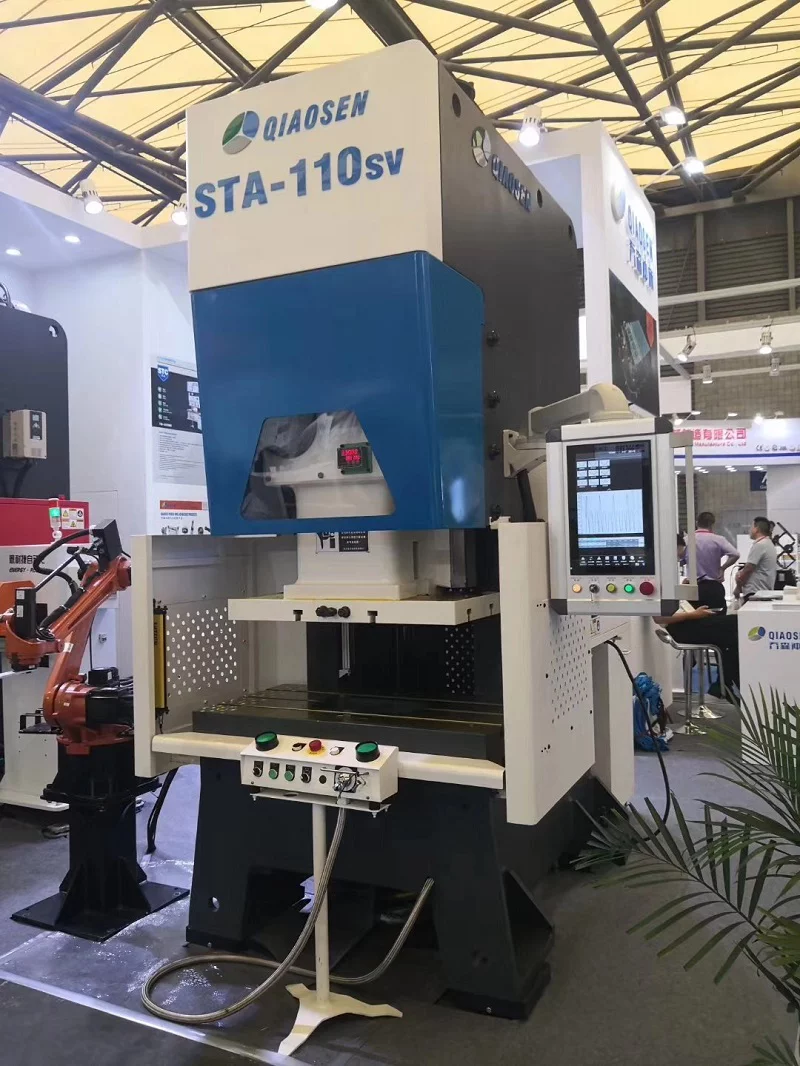

The principles and advantages of servo punching machines as well as their application scope

1. Driving mode: The servo punch is driven by a servo motor for pressure assembly operations. The pressure is directly converted by the torque output of the servo motor; while it is generally driven by a speed-regulating motor.

2. Energy saving and environmental protection: The precision CNC electronic press uses a servo motor. In its standby state, the motor does not rotate, and during the pressing process, the speed changes and the power also changes. For ordinary punch presses, the motor keeps rotating during the standby process and consumes a certain amount of power. It also rotates at a constant speed during operation, so the power consumption will be higher. Compared with ordinary motors and servo motors, the noise is also louder.

3. Precision control: Precision CNC electronic press can arbitrarily set multiple stroke speeds, precise displacement stops, precise in-position stops, precise reaching pressure stops, etc. within a certain range. Ordinary hydraulic presses are affected by the sealing of the pipeline, valve body and cylinder block, and cannot have high-precision control, and many of them are achieved with the help of mechanical limits. To approach the accuracy of electronic press control, the equipment cost will increase. It will be much higher than an electronic press and the control will be more complex.

Advantage

1: High power, miniaturization, low energy consumption. While successfully achieving high power, it also achieved significant miniaturization of the motor.

2: Durable, high stability, low failure rate, no friction-eliminating parts such as clutch and brake. Therefore, no friction, impact or vibration will occur when the slider starts and stops.

3. Ultra-low noise makes the work comfortable. During micro-movement, the operation sound is almost silent and there is no vibration.

4. High intelligence brings peace of mind, and the movement mode can be freely set according to the needs of the production workpiece.

Application scope:

Servo punching machines are widely used in the stamping and press-fitting processing of small precision parts such as precision electronics, communications, computers, household appliances, automobile parts, and motor stators and rotors.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers