How to maintain 3-in-1 decoiler and feeder and oil tank

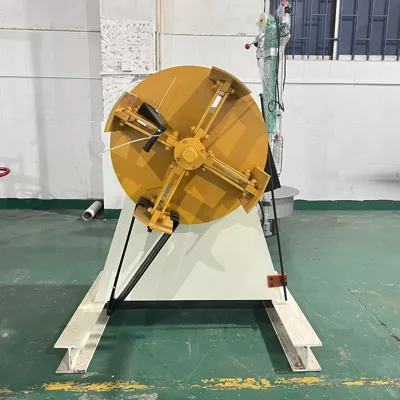

3-in-1 decoiler and feeder unit is a fully automated feeding device that combines feeding, straightening, and uncoiling functions. It is known for its high technology, precision, and efficiency. So, what are the component types and daily maintenance steps for a 3-in-1 decoiler and feeder unit, including its oil tank?

3-in-1 decoiler and feeder unit is a fully automated feeding device that combines feeding, straightening, and uncoiling functions. It is known for its high technology, precision, and efficiency. So, what are the component types and daily maintenance steps for a 3-in-1 decoiler and feeder unit, including its oil tank?

1. Component Types of a 3-in-1 decoiler and feeder Unit:

1.1 Automatic Mode:

This method is primarily used to select the automatic operation mode of the 3-in-1 decoiler and feeder unit. The decoiler and feeder unit will be in automatic mode when the automatic status light is on, and it will exit the automatic mode when the manual operation mode is selected.

1.2 Manual Mode:

This method is primarily used to select the manual operation mode of the 3-in-1 decoiler and feeder unit. Various manual operations of the decoiler and feeder unit can be performed manually. When the manual status indicator light is on, the decoiler and feeder unit will automatically exit the manual mode when the automatic operation mode is pressed.

1.3 Fault Reset:

When an alarm occurs in the 3-in-1 decoiler and feeder unit, pressing this button is necessary to reset the decoiler and feeder unit for normal operation after the alarm fault has been eliminated.

1.4 Alarm Indicator:

When materials are depleted or the machine experiences a malfunction, the machine will emit an alarm to remind the operator to replenish materials or inspect and repair the 3-in-1 decoiler and feeder unit.

1.5 OK Indicator:

The OK indicator light is used to display the operating status of the 3-in-1 decoiler and feeder unit. When the decoiler and feeder unit starts automatically, the OK light will be on.

1.6 Continuous Stop Button:

When the machine is running automatically, pressing this button will stop the automatic operation.

2. Maintenance Steps for the Oil Tank of a 3-in-1 decoiler and feeder Unit:

2.1 When the 3-in-1 decoiler and feeder unit is supplying oil during operation, the metal mesh of the oil supply port should not be removed.

2.2 When replacing the oil, the interior of the oil tank and the oil tank filter must be cleaned first.

2.3 Inspect the air filter element of the ventilation hole.

2.4 Verify the oil level indicator and ensure that the oil level is within the specified limits.

2.5 The bottom of the oil tank should be regularly drained, with the oil being sampled every 2-3 months to check for contamination and replace if necessary.

2.6 Use an oil temperature gauge to check if the oil temperature inside the oil tank is within the appropriate range, with the oil temperature near the pump inlet not exceeding 55℃.

8years foriegn trade experience Easily grasp customer needs Keeping good relationship with customers